The following is a story about a learning challenge I had in August, 2020. I was working on the largest interior project I had tackled to date, hired an employee for the 1st time, and had some technical details to figure out that were more challenging than anything I’ve done.

On a 22′ x 9′ solid wood built-in project, that was 70% complete at the time of the learning challenge, the client changed her mind on many functional and aesthetic details; combined with tight deadlines for other jobs, things were feeling overwhelming. A corner detail now needed to match the rest of the unit, house a built-in fridge, freezer, washer dryer, have enough wall clearance, ventilation detailing for all appliances, and look good.

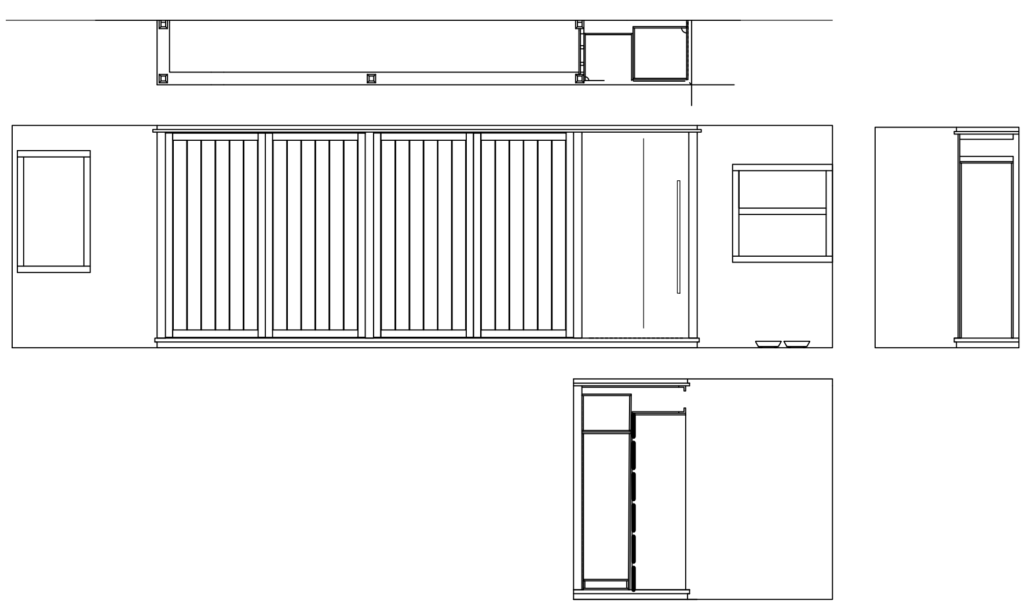

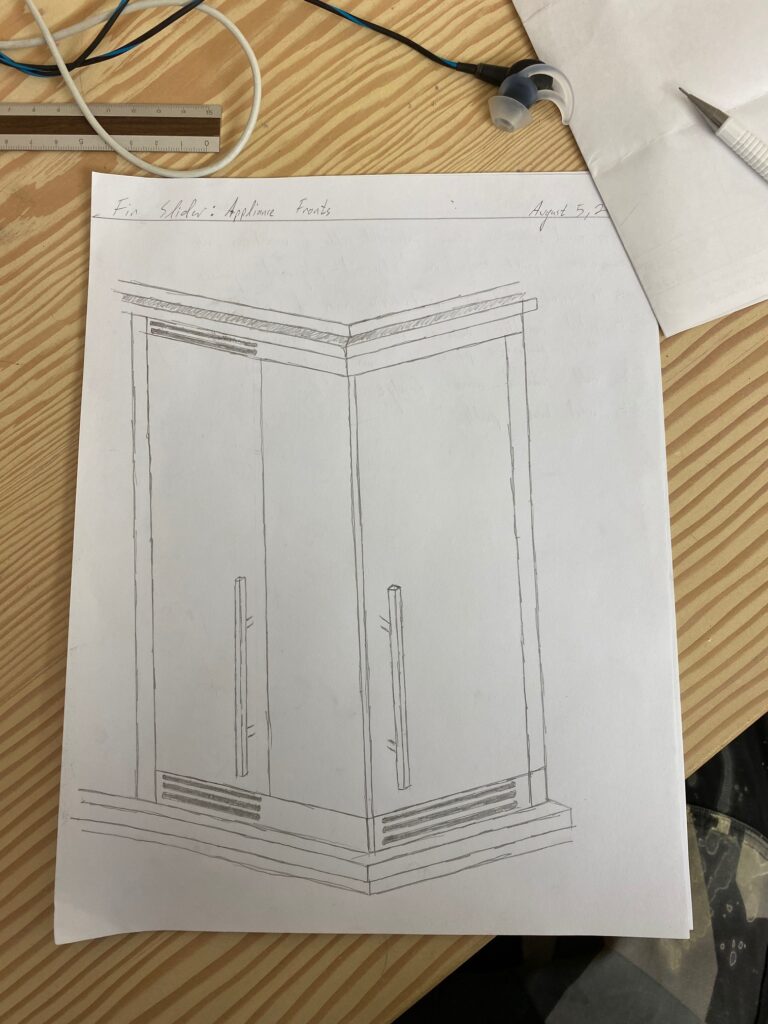

Coming up with a design that solves all technical problems, meets aesthetic goals, easily constructible, and gains client approval took a few days of only planning. Before breaking down all the requirements into manageable steps, this task felt impossible. By using an iterative approach throughout the design process, using a combination of AutoCad drawings of the existing unit, 3D modelling, hand sketching, and some random hand calculations to make sure all the dimensions worked, a design finally clicked. From there, it was just a matter of working out the technical details, exact dimension specifications, and client approval.